【法规标准】无菌产品生产的洁净室和洁净空气设备验证标准及要求

- 分类:产品知识

- 作者:超管

- 来源:利菲尔特

- 发布时间:2023-12-23

- 访问量:0

【法规标准】无菌产品生产的洁净室和洁净空气设备验证标准及要求

【概要描述】很多行业会使用无尘室,只要是小颗粒会对生产过程产生不利影响的地方都会有洁净室的身影。它们的尺寸和复杂度各不相同,广泛应用于半导体制造,制药,生物技术,医疗设备和生命科学等行业,以及航空航天,光学,军事

- 分类:产品知识

- 作者:超管

- 来源:利菲尔特

- 发布时间:2023-12-23

- 访问量:0

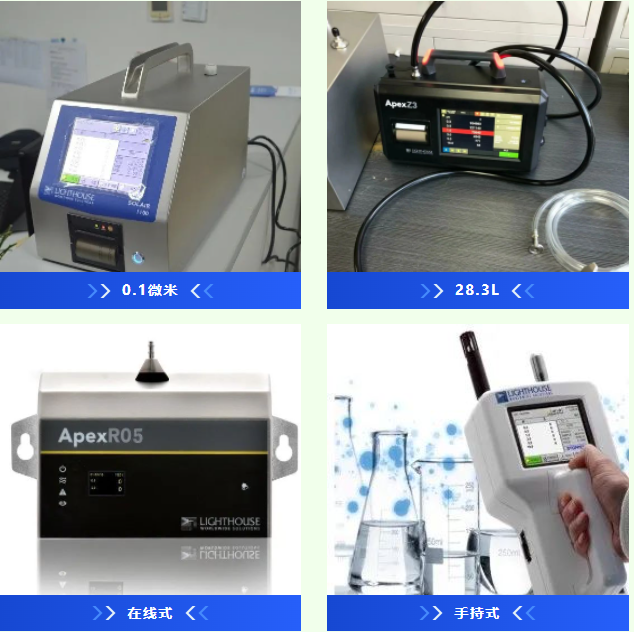

很多行业会使用无尘室,只要是小颗粒会对生产过程产生不利影响的地方都会有洁净室的身影。它们的尺寸和复杂度各不相同,广泛应用于半导体制造,制药,生物技术,医疗设备和生命科学等行业,以及航空航天,光学,军事和能源部中常见的关键工艺制造。

对于用于无菌产品生产的洁净室和洁净空气设备,需要按照GMP相关法规要求,去进行定期检测或验证,确保适当的洁净度水平,今天中邦兴业小编,跟大家分享一下关于无菌产品生产的洁净室和洁净空气设备验证标准及要求。

Cleanrooms and clean air equipment such as unidirectional airflow units (UDAFs), RABS and isolators, used for the manufacture of sterile products, should be qualified according to the required characteristics of the environment. Each manufacturing operation requires an appropriate environmental cleanliness level in the operational state in order to minimize the risk of contamination of the product or materials being handled. Appropriate cleanliness levels in the “at rest” and “operational” states should be maintained.

用于无菌产品生产的洁净室和洁净空气设备,如单向流单元(UDAF)、RABS 和隔离器,应根据所要求的环境特性进行确认。每个生产操作都要求在动态条件下达到适当的环境洁净度水平,最大程度降低所处理的产品或物料的污染风险。应维持“静态”和“动态”下的适当洁净度水平。

Cleanrooms and clean air equipment should be qualified using methodology in accordance with the requirement. Cleanroom qualification (including classification) should be clearly differentiated from operational environmental monitoring.

应使用符合要求的方法对洁净室和洁净空气设备进行确认。洁净室确认(包括分级)应与动态环境监测明确区别开来。

Cleanroom and clean air equipment qualification is the overall process of assessing the level of compliance of a classified cleanroom or clean air equipment with its intended use. As part of the qualification requirements, the qualification of cleanrooms and clean air equipment should include (where relevant to the design/operation of the installation):

洁净室和洁净空气设备的确认是评估分级的洁净室或洁净空气设备与其预期用途的符合程度的整体过程。作为的确认要求的一部分,洁净室和洁净空气设备的确认应包括(与设施的设计/运行相关的):

Installed filter system leakage and integrity testing. 已安装的过滤器系统的检漏和完整性测试。

洁净室和洁净空气设备的确认可参考 ISO 14644 系列标准。

Cleanroom classification is part of the cleanroom qualification and is a method of assessing the level of air cleanliness against a specification for a cleanroom or clean air equipment by measuring the total particle concentration. Classification activities should be scheduled and performed in order to avoid any impact on process or product quality. For example, initial classification should be performed during simulated operations and reclassification performed during simulated operations or during aseptic process simulation (APS).

洁净室分级是洁净室确认的一部分,是一种根据洁净室或洁净空气设备的标准通过测定总微粒浓度来评估空气洁净度水平的方法。分级活动的安排和执行,应避免对工艺或产品质量产生任何影响。例如,应在模拟操作期间进行初步分级,在模拟操作或无菌工艺模拟试验(APS)期间进行再分级。

For cleanroom classification, the total of particles equal to or greater than 0.5 and 5 μm should be measured. This measurement should be performed both at rest and in simulated operations in accordance with the limits specified.

对于洁净室分级,应测定等于或大于0.5μm 和 5μm 的微粒总数。应按照规定的限度,在静态和模拟操作中进行测定。

COPYRIGHT © 新乡市利菲尔特滤器股份有限公司 豫ICP备11005909号-12 XML